1. Bayanan Bayani

Double Mass Fly Wheel (DMFW) sabon tsari ne wanda ya bayyana a cikin motoci a ƙarshen 1980s, kuma yana da babban tasiri akan keɓewar girgiza da raguwar girgizar jiragen ƙasa masu ƙarfin mota.

Theruwan goroshine a raba asali na gardama zuwa kashi biyu. Bangare ɗaya ya rage a gefe ɗaya na ainihin ingin kuma yana aiki azaman ƙwanƙwasa na asali don farawa da watsa jujjuyawar jujjuyawar injin ɗin. Ana kiran wannan bangare na farko; an sanya ɗayan ɓangaren a gefen watsawa na layin tuƙi don inganta jujjuyawar jujjuyawar watsawa. , wannan bangare shi ake kira secondary mass. Akwai rami mai annular tsakanin sassan biyu, kuma an shigar da na'urar girgiza ruwan bazara a cikin rami, wanda ke da alhakin haɗa sassan biyu na jirgin sama, kamar yadda aka nuna a hoto na 1. Matsakaicin na biyu na iya ƙara lokacin inertia na jirgin ƙasa ba tare da ƙara lokacin inertia na tashi ba, kuma ya rage saurin rawa da ke ƙasa da sauri mara amfani.

Kamfanin Hexi base engine yana samar da injunan tashi sama guda biyar guda biyar, wato EK/CM/RY/SN/TB. Tashar tasha ta atomatik (OP2135) tana ƙarfafa ƙwanƙwasa biyu-mass na waɗannan injuna guda 5, kuma bolts don ƙarfafa ƙafafun ƙafar ƙafa biyu sune Torx bolts. Ana buƙatar daidaiton ƙarfafawa don zama babba, kuma ɗan karkata a cikin kusurwa zai haifar da ƙaddamarwa ba daidai ba ga shaft. A matsakaita, 15 samfurori da ba su cancanta ba sun bayyana a cikin kowane motsi, wanda ya haifar da adadi mai yawa na gyare-gyare da kuma rinjayar aikin yau da kullum na samar da layin.

A halin yanzu, tashar ƙarar gardama mai yawan jama'a tana ɗaukar hanyar sarrafawa ta juzu'i da kusurwa (35± 2) N m + (30~45) ° don saka idanu da juzu'in kusoshi. Bugu da kari, madaidaicin juzu'i na dunƙule-ƙulle-ƙulle-ƙulle-ƙulle yana da girma (buƙatun fasaha: 65 N·m ~ 86 N·m). Don saduwa da buƙatun juzu'i, ana buƙatar hannun hannu (kamar yadda aka nuna a cikin Hoto na 3) da ƙugiya ya kamata a daidaita su daidai yayin aiwatar da matsawa. A saboda wannan dalili, wannan takarda tana gudanar da bincike da bincike bisa ga ainihin matsalolin matsalolin, kuma ta ba da shawarar hanyoyin da suka dace game da yadda za a inganta ƙimar ƙwararrun ƙwararrun ƙwanƙwasa ƙafa biyu.

2. Bincika Rashin Ƙarfafa Ƙunƙarar ƙwaya

Matsala ta "tighting ba daidai ba gaKwayoyin Lug"Ya ƙunshi kashi 94.63% na adadin waɗanda ba su cancanta ba, wanda shine babban matsalar da ke haifar da ƙarancin ƙarancin ƙima na ƙwanƙwasa ƙafar ƙafar ƙafa biyu. Bayan tantance ƙayyadaddun babban matsalar, za mu iya rubuta magungunan da suka dace. Haɗe tare da yanayin yanayi da yanayin samarwa, an fayyace babban jagorar bincike.

Dangane da bayanan binciken da aka yi a halin yanzu, bayanan 459 dual-mass flywheel bolts daga Janairu zuwa Maris 2021 ba a tsaurara ba kuma an bincikar bayanan shaft, kamar yadda aka nuna a cikin Tebu 1 da Hoto 6. Bayan bincike, an gano cewa 25 daga cikin kusoshi biyu-mass flywheel sun kasa takurawa saboda gazawar da na'urar ta yi ba tare da tantancewa ba. na pallet, asarar asalin kayan aiki, lalacewa ga hannun riga, da dai sauransu, suna da babban bazuwar. Saboda haka, babban jigon wannan matsala za a iya warware ta bisa ka'ida zuwa mataki na 1-25/459=94.83%.

3. Magani

1. Maganin lalacewa na kayan aikin haƙoran haƙora na gardama

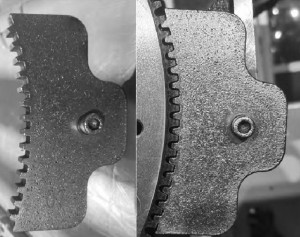

Da aka duba kayan aikin farantin gardama a wurin, an gano cewa haƙoran kayan aikin farantin gardama sun sawa sosai, kuma haƙoran ba za su iya haɗa kayan zoben gardama ba yadda ya kamata. A lokacin aikin ƙarfafa kayan aiki, ƙwanƙwasa na tashi yana girgiza, yana sa hannun riga ya yi daidai da kullun. A lokacin aikin matsewa, hannun riga ya yi tsalle daga cikin gunkin, ko kuma yana jujjuyawa a saman kullin, yana haifar da matsewar da ba ta cancanta ba.

Sauya sabon kayan aikin farantin gardama, ranar da za a yi amfani da ita a kan kayan aikin farantin gardama, sannan a maye gurbin kayan aikin kowane wata 3 don gujewa girgiza tawul ɗin a lokacin da ake yin matsewa saboda lalacewa na kambi, wanda zai haifar da ramin da bai cancanta ba.

2. Maganin kwance bayonet na tire

Bincika bayanan sake yin aikin pallet na kan-site. The reworked pallets engine sau da yawa mayar da hankali a 021#/038#/068#/201#. Sa'an nan kuma aka duba pallets kuma an gano cewa palette gyara fil ɗin ba su da kullun. Sakamakon haka, hannun rigar baya daidaitawa tare da ƙugiya, hannun riga ya yi tsalle daga cikin kusoshi yayin aiwatar da matsewa, ko raɗaɗi a saman kullin yana haifar da ƙarar da ba ta cancanta ba. Idan an sassauta ƙullun gyaran katako na pallet bayoneti, ba za a iya gyara bayonet ɗin yadda ya kamata. Don gyaran toshe na pallet, yi amfani da tsawaitaccen kusoshi (da gajerun kusoshi), kuma a yi amfani da ɓangarorin sassautawa na baya-bayan nan don gyara su don guje wa ɓangarorin bayoneti wanda ya haifar da sassaukar da kusoshi na pallet bayoneti. Ba za a iya daidaita shi yadda ya kamata ba, yana haifar da girgizawar tashi da ɓatar da sandar a yayin aikin ƙarfafawa, wanda bai cancanta ba.

3. Haɓaka hanyar ɗaukar hotuna na kyamarar na'urar

Wannan mataki shine mafi wahala na shirin. Saboda babu sigogi da za a yi la'akari da su, ya zama dole don bincika da sarrafa kayan aiki. Takamammen tsari:

(1) Sake gyara daidaitawar asali

(2) Haɓaka shirin ma'aunin ramuwa na cibiyar hoto na kyamara, kamar tsakiyar rami na hoto, saita ƙimar diyya da adadin gyara don daidaitawar cibiyar, da kuma gyara madaidaicin rami na tsakiya.

(3) Daidaita ƙimar diyya mai fallasa kamara.

An ci gaba da bin diddigin bayanan kuma ana tattara su har tsawon watanni 3. A cikin wannan lokacin, ƙimar cancantar ƙarar ƙugiya mai yawan jama'a sau biyu, kuma an yi gyare-gyare da gyare-gyare masu dacewa ga ma'aunin hoto. A farkon Afrilu, an daidaita ƙimar diyya mai ɗaukar hoto daga 2 800 zuwa 2 000, kuma ƙimar cancantar ƙarar ta ƙara zuwa 97.75%. , an sami ƙarin gazawa bayan aikin bin diddigin, sa'an nan kuma an daidaita ƙimar bayyanar kyamara: daga 2 000 zuwa 1 800, wanda ya karu zuwa 98.12%; don ƙarfafa matakan, yayin aiwatar da bin diddigin, an sake inganta ƙimar bayyanar kyamara: daga 1 800 ya zama 1 000, kuma ƙimar wucewa ta ƙarshe ta ƙarshe a cikin Afrilu ya karu zuwa 99.12%; An ci gaba da bin diddigin ƙimar izinin wucewa a cikin Mayu da Yuni zuwa sama da 99%.

4. Cin duri

The ruwan goroFlywheel shine na'urar da ke da mafi kyawun keɓewar jijjiga da tasirin rage girgiza akan motar yanzu. Girgizawar injin dizal ya fi na injin mai. Domin rage girgiza injin dizal da kuma inganta jin daɗin hawan, yawancin motocin fasinja na dizal a Turai yanzu suna amfani da ƙaya biyu masu yawa, ta yadda jin daɗin injin dizal ɗin ya yi daidai da na motar injin mai [6]. A kasar Sin, na'urar watsa da hannu ta FAW-Volkswagen's Bora ta dauki nauyin daukar matakai na tashi sama. Bukatar kasuwa don ƙaya biyun na ci gaba da faɗaɗa, kuma buƙatun ƙarfafa ƙimar cancanta suma suna ƙaruwa [7]. Wannan labarin ya nazarci matsalolin gama gari waɗanda ke haifar da ƙunshewar ƙwanƙwasa ƙafar ƙafa biyu marasa cancanta, gano tushen tushen, tsara hanyoyin magance matsala, da kuma magance matsalar. A halin yanzu, kayan aiki suna aiki da kyau, kuma ƙimar wucewa ya kasance sama da 99%. Maganin wannan matsala yana da ma'ana mai kyau don ceton farashin aiki da inganta ingancin masana'anta.

Lokacin aikawa: Satumba-29-2022