1. Halayen Tsari Na Aikin Aiki

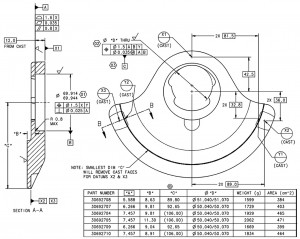

Siffar kayan aikin bakin ciki-bangodabaran nauyisiffa ce ta fan, kayan shine QT600, taurin shine 187-255 HBW, ciki shine rami mai siffa na musamman, kuma mafi ƙarancin ɓangaren kauri ne kawai 4 mm. Ana nuna buƙatun daidaito na ma'auni na ma'auni a cikin Hoto 1. Matsakaicin diamita na rami na tsakiya B shine Φ69.914-69.944 mm, kuma haƙuri shine kawai 0.03 mm. A ƙasa akwai ramin da ba komai ba. Ana yin yankan tsaka-tsaki lokacin yin aikin rami na C da da'irar waje. Kaurin bango a nan shine kawai 4 mm, wanda yake da sauƙi don haifar da yanke danniya da lalacewa kuma yana shafar girman juriya na rami na B, wanda shine matsala mai wuyar gaske a cikin sarrafa kayan aiki.

2. Boyewar Hatsarin Sana'o'in Gargajiya

Sassan ɓangarorin bakin bango suna da sauƙi nakasu yayin aikin niƙa, galibi saboda nakasar da ke haifar da yanke damuwa da matsewa. Tsarin sarrafa kayan gargajiya ana sarrafa shi ta hanyar CNC machining center da CNC lathe, wanda ya kasu kashi biyu. Ɗaya shine tsarin OP10. Yi amfani da abin yankan niƙa na 60mm diski don ƙaƙƙarfan kuma ƙarasa babban jirgin sama zuwa girman zane, yi amfani da abin yankan alloy milling Φ20 mm don niƙa ramin ciki Φ51.04-51.07 mm zuwa Φ50.7 mm (bar 0.3-0.4 mm), yi amfani da Φ20 milling Φ20. Φ69.914 ~ 69.944 mm zuwa Φ69.6 mm (bar 0.3 ~ 0.4 mm), rami mai ban sha'awa mai kyau na ciki Φ51.04 Na biyu shine tsarin OP20. Da'irar waje "C" na m da kyau juya shi ne zuwa fasaha bukatun na zane.

Wahalhalun machining nadabaran nauyi, ramin tunani B, an yi amfani da shi zuwa girman da ake buƙata ta zane a cikin tsarin OP10. Cire aikin aikin kuma auna diamita na ramin tunani B, Φ69.914 ~ 69.944 mm, kuma kuskuren ovality shine 0.005 ~ 0.015 mm, kuma girman ya dace da bukatun zane. Koyaya, bayan an sarrafa OP20, cire kayan aikin kuma auna diamita na rami na B, Φ69.914-69.944 mm, kuma kuskuren ovality shine 0.03-0.04 mm. Ana iya ganin cewa diamita ya wuce bukatun zane.

3. Magani

Inganta kayan aiki. Ko ƙirar na'urar ƙwanƙwasa daidai tana da tasiri kai tsaye akan tabbatar da daidaiton mashin ɗin kayan aikin, haɓaka yawan aiki da rage ƙarfin aiki na ma'aikata. Saboda halaye na sassa na bakin ciki, matsananciyar matsananciyar ƙarfi ko ƙarfin da bai dace ba zai haifar da nakasar nakasar kayan aikin, wanda zai shafi daidaiton girman da siffar juriya na ɓangaren, kuma a ƙarshe ya haifar da girman ɓangaren da aka sarrafa ba tare da haƙuri ba. Don magance wannan matsala, samfurin da girman girman silinda mai ƙwanƙwasa da silinda mai goyan baya ya kamata a zaɓa a hankali lokacin zayyana kayan aikin hydraulic.

Lokacin aikawa: Agusta-19-2022