1. Taƙaice

Zaren ciki da aka yi amfani da shi ta igiyoyin ruwa mai tsayi kuma aka zaɓa don amfani da shitalakawa kusoshida kusoshi na kulle kai, waɗanda aka daidaita su ta hanyoyi daban-daban na ƙarfafawa, kuma ana nazarin bambanci tsakanin ƙulla anka da kulle-kulle calibration anchoring halaye masu lankwasa. Sakamako: Hanyar ƙwanƙwasa da ƙuƙwalwar ƙira za ta sami siffofi daban-daban na daidaitawa, ma'auni na kulle lokaci na sarkar ya sa ƙaddamar da kai da kai da kuma lokacin da aka yi amfani da shi don ƙaddamar da kai ga maƙasudai daban-daban. Saboda madaidaicin motsi na al'ada, abubuwan da aka samu daban-daban za su matsa zuwa dama .

2. Gwaji Falsafa

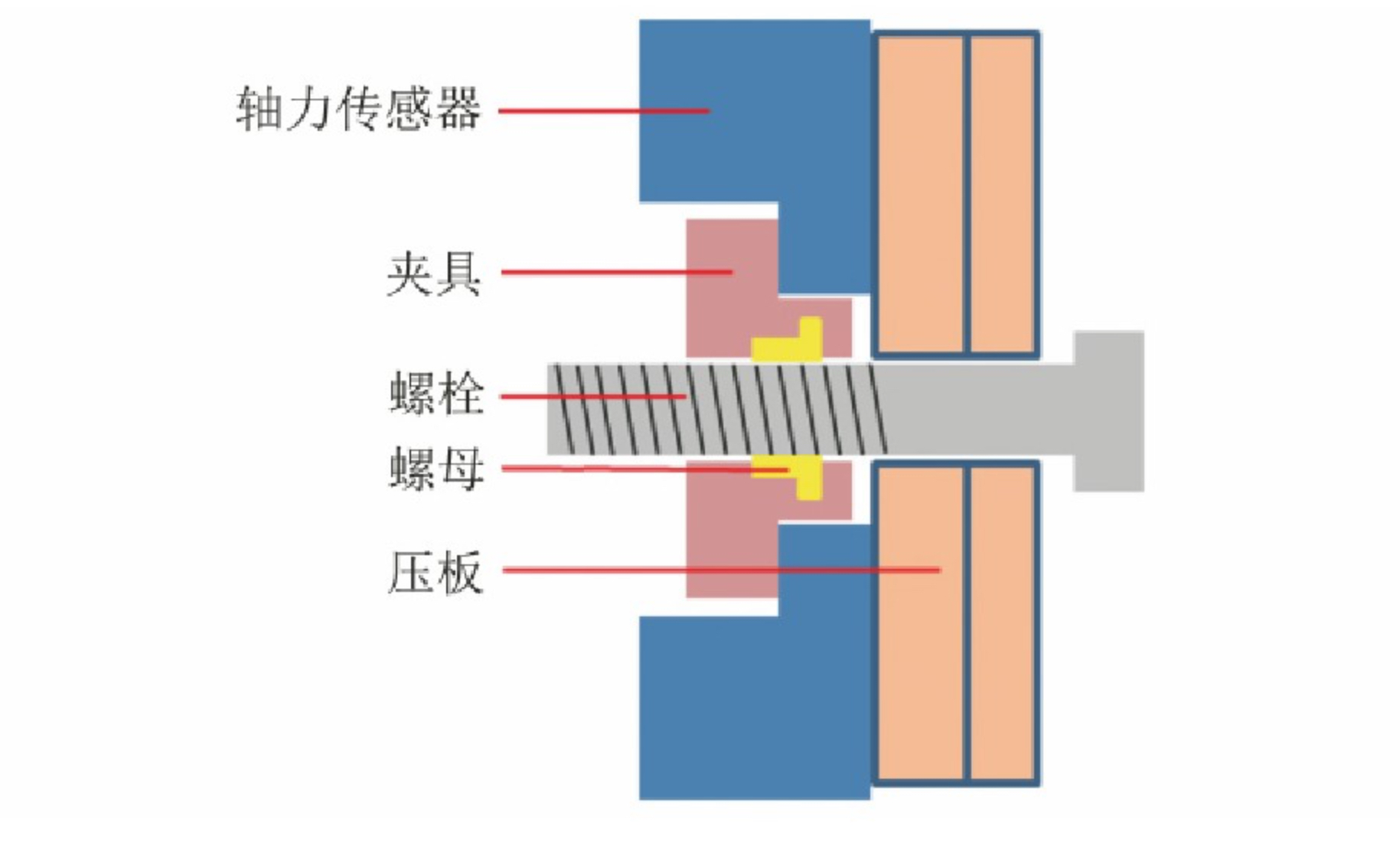

A halin yanzu, ana amfani da hanyar ultrasonic sosai a cikingwajin ƙarfin axialna madaidaicin madaidaicin tsarin tsarin mota, wato, alaƙar sifa mai lanƙwasa (ƙwanƙwalwar ƙira) tsakanin ƙarfin axial da ƙarfin sauti na ultrasonic an samu a gaba, kuma ana aiwatar da gwajin na gaba na ainihin tsarin subsystem. The axial ƙarfi na aron kusa a tightening dangane za a iya samu ta ultrasonically aunawa da sautin lokaci bambanci na aronji da kuma nufin calibration kwana. Don haka, samun madaidaicin madaidaicin daidaitawa yana da mahimmanci musamman don daidaiton sakamakon ma'aunin ƙarfin axial a cikin ainihin tsarin ɓangaren ɓangaren. A halin yanzu, hanyoyin gwajin ultrasonic galibi sun haɗa da hanyar igiyar igiyar ruwa guda ɗaya (watau hanyar igiyar ruwa a tsaye) da kuma karkatar da hanyar igiyar ruwa mai tsayi.

A cikin tsarin gyaran gyare-gyare na bolt, akwai abubuwa da yawa waɗanda ke shafar sakamakon daidaitawa, kamar tsayin daka, zafin jiki, saurin na'ura, kayan aiki na kayan aiki, da dai sauransu. A halin yanzu, hanyar da aka fi amfani da ita ta hanyar daidaita sautin ƙararrawa ita ce hanyar jujjuyawa. An daidaita maƙallan a kan benci na gwaji na bolt, wanda ke buƙatar samar da kayan aiki masu goyan baya don firikwensin ƙarfin axial, wanda shine farantin matsa lamba da ƙuƙwalwar ƙuƙwalwar ciki. Ayyukan ƙwanƙwasa zaren rami na ciki shine ya maye gurbin kwayoyi na yau da kullun. Ana amfani da ƙira marar sako-sako da yawa a wuraren haɗin haɗin gwiwa tare da babban yanayin aminci na chassis na mota don tabbatar da amincin ɗaurin sa. Daya daga cikin matakan hana sako-sako da aka dauka a halin yanzu shine goro mai kulle kai, wato, goro na kulle mai inganci.

Marubucin ya yi amfani da hanyar igiyar igiyar ruwa mai tsayi kuma yana amfani da na'urar gyare-gyaren zaren ciki don zaɓar goro na yau da kullun da na goro mai kulle kai don daidaita gunkin. Ta hanyar dabaru daban-daban na matsawa da hanyoyin daidaitawa, ana nazarin bambanci tsakanin goro na yau da kullun da na goro mai kulle kai don daidaita lankwasa. Gwajin ƙarfin axial na na'urorin haɗin keɓaɓɓen tsarin mota yana ba da wasu shawarwari.

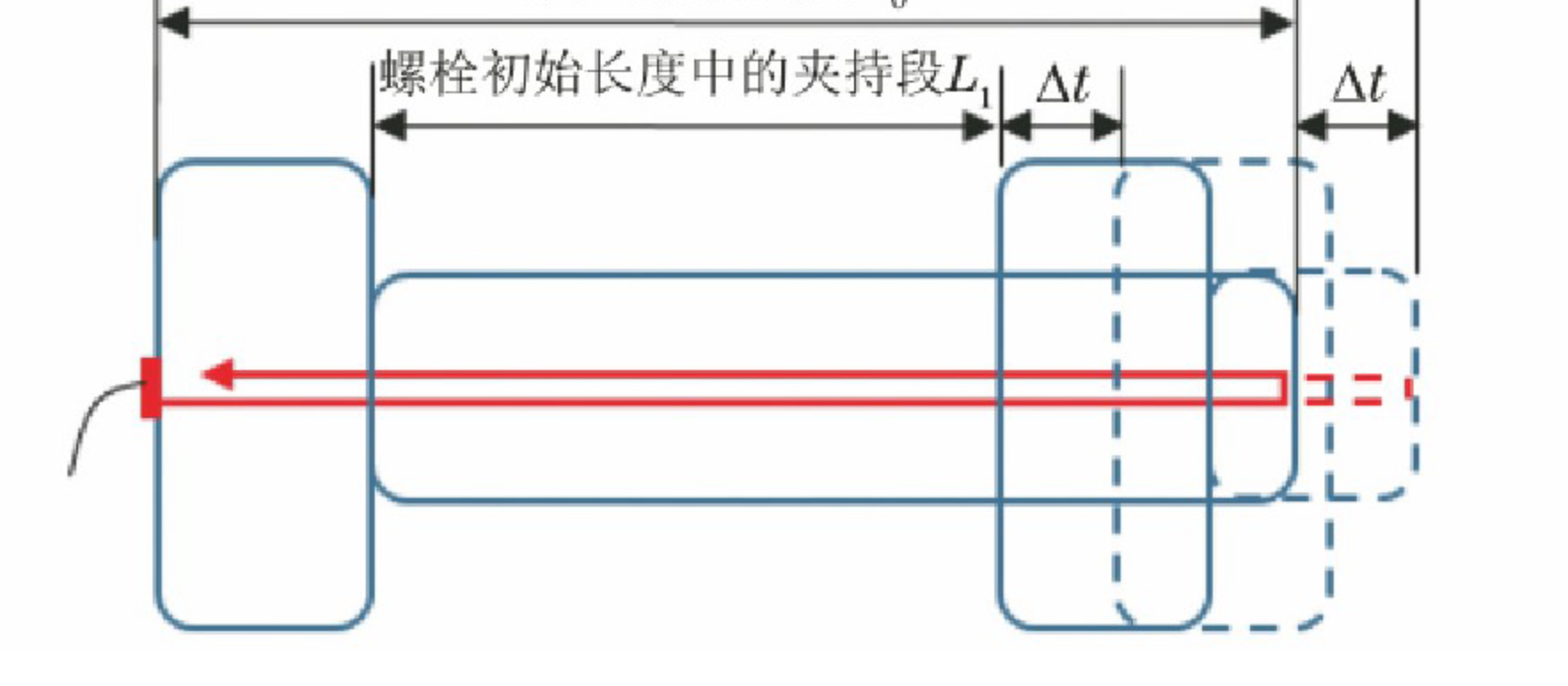

Gwajin ƙarfin axial na kusoshi ta fasahar ultrasonic hanya ce ta gwaji kai tsaye. Dangane da ka'idar sonoeelasticity, saurin yaduwar sauti a cikin daskararru yana da alaƙa da damuwa, don haka ana iya amfani da raƙuman ruwa na ultrasonic don samun ƙarfin axial na kusoshi [5-8]. Ƙaƙwalwar za ta shimfiɗa kanta a lokacin aikin ƙarfafawa, kuma a lokaci guda yana haifar da damuwa na axial. Za a watsa bugun jini na ultrasonic daga kan ƙugiya zuwa wutsiya. Saboda canjin kwatsam a cikin matsakaicin matsakaicin matsakaici, zai dawo tare da hanyar asali, kuma saman kullun zai karbi siginar ta hanyar yumburan piezoelectric. bambancin lokaci Δt. Ana nuna zane-zane na gwaji na ultrasonic a cikin Hoto 1. Bambancin lokaci yana daidai da elongation.

Gwajin ƙarfin axial na kusoshi ta fasahar ultrasonic hanya ce ta gwaji kai tsaye. Dangane da ka'idar sonoeelasticity, saurin yaduwar sauti a cikin daskararru yana da alaƙa da damuwa, don haka ana iya amfani da raƙuman ruwa na ultrasonic don samun.karfin axial na kusoshi. Ƙaƙwalwar za ta shimfiɗa kanta a lokacin aikin ƙarfafawa, kuma a lokaci guda yana haifar da damuwa na axial. Za a watsa bugun jini na ultrasonic daga kan ƙugiya zuwa wutsiya. Saboda canjin kwatsam a cikin matsakaicin matsakaicin matsakaici, zai dawo tare da hanyar asali, kuma saman kullun zai karbi siginar ta hanyar yumburan piezoelectric. bambancin lokaci Δt. Ana nuna zane-zane na gwaji na ultrasonic a cikin Hoto 1. Bambancin lokaci yana daidai da elongation.

M12 mm × 1.75 mm × 100 mm sa'an nan da ƙayyadaddun kusoshi, yi amfani da talakawa kusoshi gyara 5 irin wannan kusoshi, da farko amfani da kai-anga gwajin da daban-daban siffofin calibration solder manna, shi ne wucin gadi karkace farantin zuwa aron kusa flange fit da kuma latsa Lokacin Ana dubawa na farko kalaman (wato, rikodin sa'an nan 0 ° N0 kayan aiki tare da shi) da kuma 3 m. (wanda ake kira hanyar nau'in I), ɗayan kuma shine a duba igiyar farko kuma a murƙushe shi zuwa girman abin da aka nufa tare da ƙarar bindiga (wanda ake kira hanyar nau'in I). Don hanyar nau'in nau'i na biyu), za a sami wani nau'i a cikin wannan tsari (kamar yadda aka nuna a hoto na 4) 5 shine kullun talakawa da kuma hanyar kulle kai Ƙaƙwalwar bayan calibration bisa ga nau'in nau'in I Hoto 6 shine nau'in kulle kai. Hoto na 6 aji ne mai kulle-kulle. Masu lanƙwasa Class I da Class II. Hanyar yin amfani da ita na iya zama, yi amfani da madaidaicin al'ada na rukunin anka na gama gari, daidai iri ɗaya (duk suna wucewa ta asali tare da ƙimar kashi ɗaya da adadin maki); kulle nau'in index na nau'in maki (nau'in I da alamar anga, gangara na bambancin tazara da adadin maki); samun kamanceceniya)

Gwaji na 3 shine saita daidaitawar Y3 na Saiti na Graph a cikin software na kayan aikin sayan bayanai azaman daidaitawar zafin jiki (ta amfani da firikwensin zafin jiki na waje), saita nisan gunkin zuwa 60 mm don daidaitawa, da yin rikodin ƙarfin juyi / axial ƙarfi/zazzabi da madaidaicin kusurwa. Kamar yadda aka nuna a cikin hoto na 8, ana iya ganin cewa tare da ci gaba da screwing na bolt, zafin jiki yana ci gaba da tashi, kuma ana iya ɗaukar hawan zafi a matsayin mai layi. An zaɓi samfuran kullu guda huɗu don daidaitawa tare da ƙwaya masu kulle kai. Hoto na 9 yana nuna ma'aunin daidaitawa na kusoshi huɗu. Ana iya ganin cewa lanƙwasa huɗu duk an fassara su zuwa dama, amma matakin fassarar ya bambanta. Tebur 2 yana yin rikodin nisa wanda madaidaicin madaidaicin ke motsawa zuwa dama da haɓakar zafin jiki yayin aikin ƙarfafawa. Ana iya ganin cewa matakin madaidaicin jujjuyawar da ke jujjuyawa zuwa dama yana daidai da karuwar zafin jiki.

3. Kammalawa da Tattaunawa

An ƙaddamar da kullin zuwa aikin haɗin gwiwa na damuwa na axial da damuwa na torsional yayin daɗaɗɗa, kuma sakamakon ƙarfin da ke haifar da su a ƙarshe yana haifar da kusoshi don samarwa. A cikin daidaitawar kusoshi, kawai ƙarfin axial na ƙullun yana nunawa akan madaidaicin daidaitawa don samar da ƙarfin matsawa na tsarin haɗin gwiwa. Ana iya gani daga sakamakon gwajin da ke cikin hoto na 5 cewa, duk da cewa goro ne mai kulle kansa, idan aka rubuta tsawon farko bayan an jujjuya kullin da hannu zuwa inda zai dace da saman matsi na farantin matsi, sakamakon lanƙwan daidaitawa gaba ɗaya ya yi daidai da na goro na yau da kullun. Wannan yana nuna cewa a cikin wannan hali, tasirin kullin kulle kansa na goro na kulle kansa ba shi da komai.

Idan an kulle kullin kai tsaye a cikin goro mai kulle kai tare da bindigar lantarki, lanƙwan za ta matsa zuwa dama gaba ɗaya, kamar yadda aka nuna a hoto na 6. Wannan yana nuna cewa jujjuyawar kulle kai tsaye tana rinjayar bambancin lokacin sauti a cikin ma'aunin daidaitawa. Yi la'akari da sashin farko na lanƙwasa wanda aka canza zuwa dama, yana nuna cewa har yanzu ba a samar da ƙarfin axial ba a ƙarƙashin yanayin cewa kullin yana da wani adadin tsayin daka, ko kuma ƙarfin axial yana da ƙananan ƙananan, wanda yake daidai da cewa ba a danna gunkin a kan firikwensin ƙarfin axial ba. Mikewa, a bayyane yake elongation na kusoshi a wannan lokacin shine elongation na ƙarya, ba ainihin elongation ba. Dalilin arya elongation shi ne cewa zafi samar da kai-kulle karfin juyi a lokacin da iska tightening tsari rinjayar da yaduwa na ultrasonic taguwar ruwa, wanda aka nuna a kan kwana. Ya nuna cewa an yi tsayin daka, yana nuna cewa zafin jiki yana da tasiri akan igiyoyin ultrasonic. A cikin hoto na 6, ana amfani da goro mai kulle kai don daidaitawa, amma dalilin da yasa ma'aunin calibration ba ya motsawa zuwa dama shi ne, ko da yake akwai rikici lokacin da ake yin kullun a cikin na'urar kulle kai, zafi yana haifar da zafi, amma an haɗa zafi a cikin rikodin tsawon farkon kullin. An share shi, kuma lokacin ƙulla ƙididdiga yana da ɗan gajeren lokaci (yawanci kasa da 5s), don haka tasirin zafin jiki ba ya bayyana akan yanayin yanayin daidaitawa.

Ana iya gani daga binciken da ke sama cewa gogayyawar zaren a cikin iska yana haifar da zafin jiki ya tashi, wanda ke rage saurin igiyar ruwa na ultrasonic, wanda ke bayyana a matsayin madaidaicin motsi na madaidaicin madaidaicin zuwa dama. Torque, duka biyun sun yi daidai da zafin da aka haifar ta hanyar zaren zaren, kamar yadda aka nuna a cikin Hoto na 10. A cikin Table 2, ana kirga girman madaidaicin madaidaicin madaidaicin ma'auni da kuma yawan zafin jiki na kusoshi a lokacin duk aikin ƙarfafawa. Ana iya ganin cewa girman madaidaicin madaidaicin madaidaicin madaidaicin daidai yake da ma'aunin haɓakar zafin jiki, kuma yana da alaƙar madaidaicin madaidaiciya. Matsakaicin shine kusan 10.1. Tsammanin cewa zafin jiki yana ƙaruwa da 10°C, bambancin lokacin sauti yana ƙaruwa da 101ns, wanda yayi daidai da ƙarfin axial na 24.4kN akan madaidaicin ƙararrawa na M12. Daga ra'ayi na jiki, an bayyana cewa karuwar zafin jiki zai haifar da resonant dukiya na abin rufewa don canzawa, don haka saurin motsi na ultrasonic ta hanyar matsakaicin matsakaicin canje-canje sannan kuma ya shafi lokacin yaduwar ultrasonic.

4. Shawara

Lokacin amfani da goro na yau da kullun dagoro mai kulle kaidon daidaita ma'auni na sifa na ƙwanƙwasa, za a sami nau'i-nau'i na ƙididdiga daban-daban saboda hanyoyi daban-daban. The tightening karfin juyi na kai-kulle goro yana ƙara yawan zafin jiki na angwaye, wanda ƙara ultrasonic lokaci bambanci, da samu calibration halayyar kwana zai matsa zuwa dama a layi daya.

A lokacin gwajin dakin gwaje-gwaje, ya kamata a kawar da tasirin zafin jiki a kan igiyar ruwa ta ultrasonic kamar yadda zai yiwu, ko kuma a aiwatar da hanyar daidaitawa iri ɗaya a cikin matakai biyu na ƙirar ƙira da gwajin ƙarfin axial.

Lokacin aikawa: Oktoba-19-2022