1. Matsaloli a Tsarin Taro na Ƙaƙwalwar Valve

A cikin wannan binciken, bayan da aka shayar da ƙwarewar ƙira na sauran tsarin haɗin kai ta atomatik, an yi nazarin tsarin haɗakarwa ta atomatik na yanzu, kuma an tsara ɓangaren injin ɗin gabaɗaya dangane da simulation nabawul coretsarin taro. A cikin tsarin tsarin tsarin, muna ƙoƙari don yin aiki na kayan aikin injiniya ya dace, rage yawan farashi, yin haɗuwa da sassa masu sauƙi da sauƙi, da kuma sanya tsarin yana da wani nau'i na budewa da fadadawa, don haɓaka aminci da ingantaccen tsarin. , da kuma kafa tushe mai kyau don inganta ayyukan farashi na tsarin.

Thebawulcibiyatsarin taro ya kasu kashi uku ne dangane da tsarin tsarin injinsa, wato: sassa biyu a kusurwar hagu na sama na wurin aiki, sassa uku a kusurwar hagu na ƙasa da sassa bakwai a gefen dama na sashin aikin. Ƙwararrun fasaha na haɗuwa guda biyu yana dogara ne akan yadda za a tabbatar da siffar madauwari na zoben rufewa. A lokacin aikin yankewa, za a yi amfani da shi ga ƙarfin extrusion na axial na ruwa, don haka yana da sauƙi don lalata . Abu na biyu, a lokacin tsarin haɗin gwiwa, lokacin da aka gano sandar igiya a kan kayan aikin kayan aiki na canja wuri, ya zama dole don gane nunawa da haɗuwa tsakanin sassa daban-daban na ƙofa ta hanyar girgiza. Sabili da haka, kowane sashi ya faɗi cikin matsayi mai dacewa don zama haɗin haɗin haɗin gwiwa. Wahalar tsari ta ta'allaka ne a cikin. Matsalolin da ke sama sune manyan dalilan haɓakar ƙarancin samfura a cikin babban taro na bawul a wannan matakin. Bisa ga wannan, wannan takarda yana inganta tsarin tsarin haɗin ɓangarorin bawul, kuma yana ƙara tsarin dubawa mai inganci don inganta ƙimar cancantar haɗin ginin valve.

2. Intelligent Valve Core Assembly Scheme

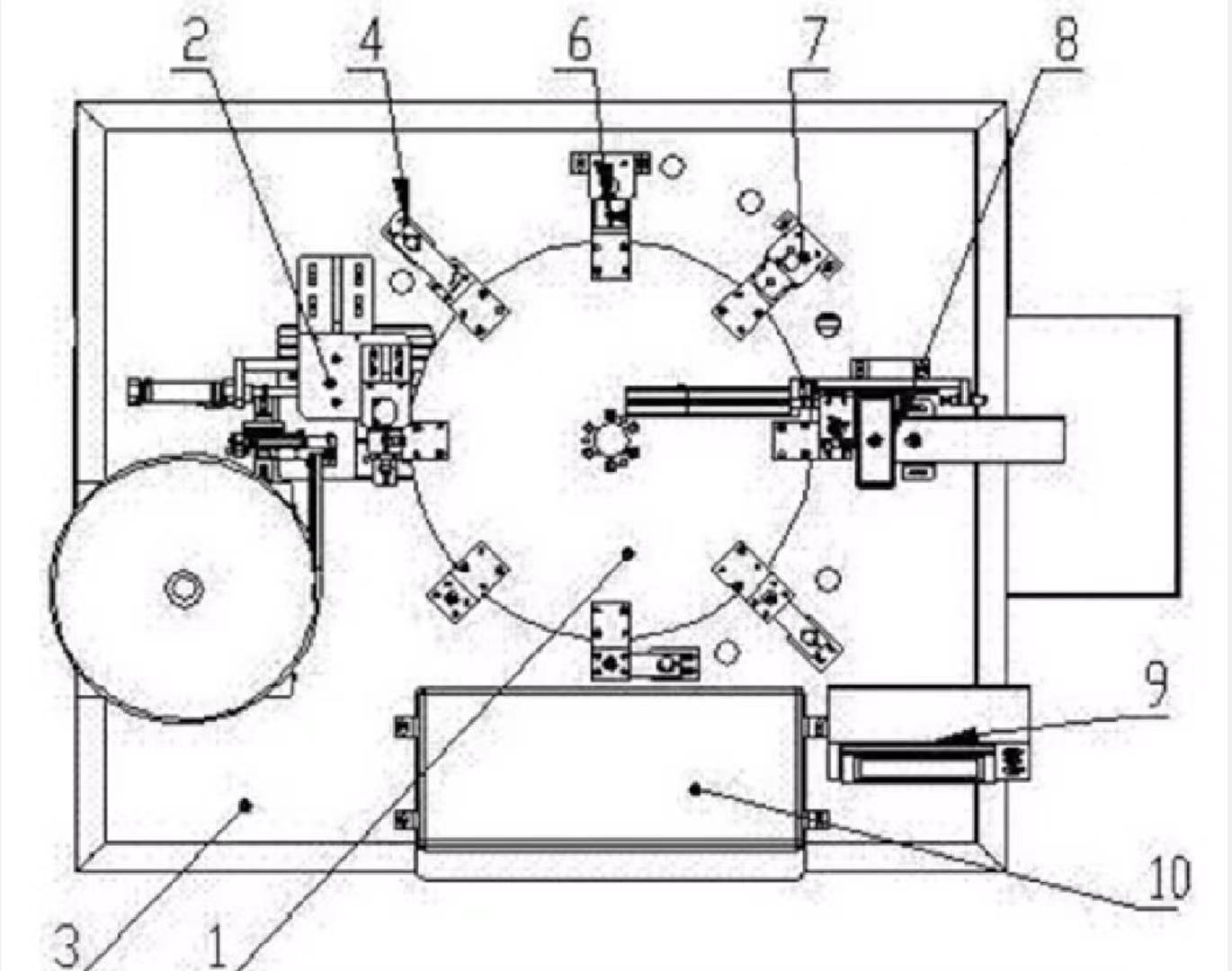

Ƙwararren aiki da PLC suna samar da wani ɓangare na sarrafawa na tunani, kuma tsarin ganowa da PLC suna da bayanai guda biyu don tattara bayanan matsayi na tsarin taro da kuma fitar da siginar sarrafawa. A matsayin ɓangaren zartarwa, tsarin tuƙi ana sarrafa shi kai tsaye ta ɓangaren fitarwa na PLC. Sai dai tsarin ciyarwa, wanda ke buƙatar taimakon hannu, sauran matakai a cikin wannan tsarin sun sami haɗin kai na hankali. Ana samun kyakkyawar hulɗar ɗan adam da kwamfuta ta hanyar allon taɓawa. Yin la'akari da dacewa na aiki a cikin ƙirar injiniya, akwatin saƙon ƙofar ƙofar yana kusa da allon taɓawa. The ganewa inji, kofa core top-bude hurawa bangaren, da bawul core tsawo ganewa bangaren da blanking inji suna bi da bi a kusa da turntable tooling bangaren, gane da taron line samar layout na ƙofar core taro. The ganewa tsarin yafi kammala core sanda ganowa, shigarwa tsawo ganewa, ingancin dubawa, da dai sauransu, wanda ba kawai gane da aiki da kai na abu selection da bawul core kulle, amma kuma tabbatar da kwanciyar hankali da kuma high dace da taro tsari. Ana nuna tsarin kowace naúrar tsarin a hoto na 1.

Kamar yadda aka nuna a cikin hoton da ke ƙasa, turntable shine cibiyar sadarwa ta tsakiya na dukkanin tsari, kuma an kammala taron ɓangarorin bawul ɗin ta hanyar tuƙi na turntable. Lokacin da na'urar ganowa ta biyu ta gano ɓangaren da za a haɗa, ta aika da sigina zuwa tsarin sarrafawa, kuma tsarin sarrafawa yana daidaita aikin kowane ɓangaren tsari. Da farko, faifan jijjiga yana girgiza ainihin ƙofar kuma ya kulle shi a bakin bawul ɗin sha. Na'urar ganowa ta farko za ta yi la'akari kai tsaye ga ma'aunin bawul ɗin da ba a samu nasarar shigar da su azaman abubuwa mara kyau ba. Bangaren 6 yana gano ko iskar bakin bawul ɗin ya cancanta, kuma sashi na 7 yana gano ko tsayin shigarwa na bawul core ya dace da ma'auni. Samfuran da suka cancanta a cikin hanyoyin haɗin kai guda uku da ke sama za a kama su a cikin akwati mai kyau, in ba haka ba za a kula da su azaman samfuran lahani.

Majalisar masu hankali tabawul coreshine wahalar fasaha na ƙirar tsarin. A cikin wannan zane, ana ɗaukar ƙirar silinda uku. Silinda ta zamewa tana sarrafa fitarwa don tabbatar da keɓantawar fitarwa; Silinda na biyu yana tabbatar da cewa sandan kulle yana daidaitawa tare da ramin fitarwa, sannan ya yi aiki tare da silinda na silinda don kammala maɓallin bawul ɗin da ke shiga sandar kulle, sa'an nan kuma Silinda ta biyu ta ci gaba da tura duk hanyar kulle don motsawa, kuma bututun tsotsa zai tsotse bawul lokacin da ya isa kasan kayan aikin. A ƙarshe, bayan silinda na uku ya tura na'urar kullewa zuwa wurin, motar servo tana aika da bawul core zuwa bakin bawul ɗin ci don kammala haɗuwa da maɓallin bawul. Wannan tsari yana tabbatar da daidaito da bambancin matsayi na motsi na tsaye da na gefe, kuma yana ba da mafita mai kyau ga matsalolin fasaha na haɗin ginin kofa..

3. Zane na Maɓallin Maɓalli na Tsarin Taro na Valve Core

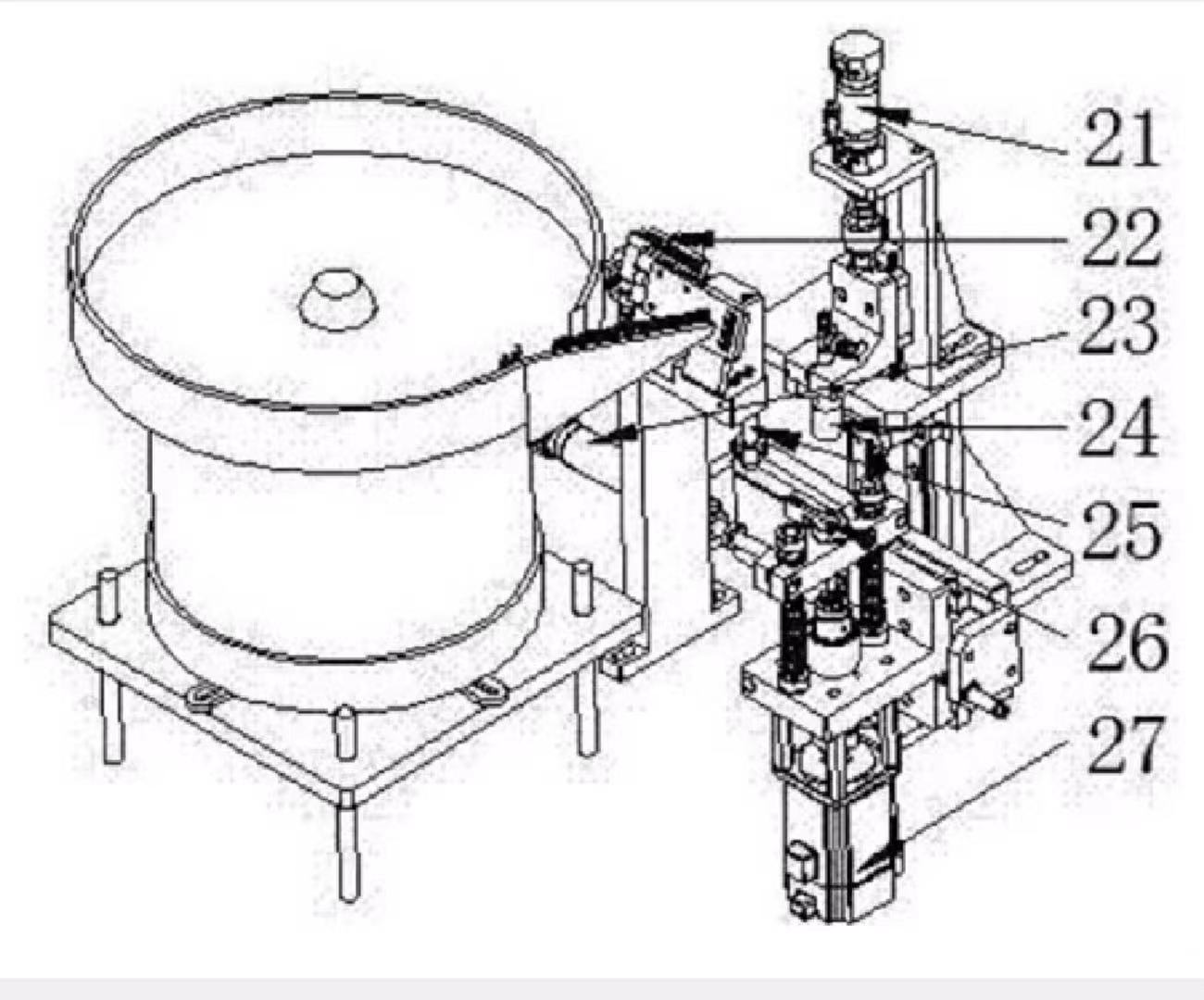

Kamar yadda key tsari na installing dabawul corea kan bawul ɗin, kulle maɓallin bawul ɗin yana da buƙatu masu yawa akan daidaiton yanayin motsi na ɗigon bawul, don haka yana buƙatar daidaitawar hanyoyin madaidaiciya da na gefe don kammalawa. A cikin zane na wannan ɓangaren, an lalata shi a cikin aiki guda ɗaya, aikin fitarwa na ƙwanƙwasa ƙwanƙwasa, aikin kullewa na maƙallan kullewa da kuma aikin ɗaukar nauyin bawul a kan bututun valve. An nuna tsarin injinsa a cikin Hoto 2. Kamar yadda ake iya gani daga Hoto na 2, tsarin injiniya na haɗin ginin valve ya kasu kashi uku. Sassan uku suna aiki cikin daidaituwa ba tare da shafar juna ba. Lokacin da aka kammala aikin mai zaman kansa, silinda yana tura injin don matsawa zuwa matsayi na gaba.

Don tabbatar da daidaiton matsayi na motsi, ana ɗaukar cikakkiyar ƙirar sarrafa wutar lantarki da iyakar injin don sarrafa kuskuren cikin 1.4mm. Bawul core da tsakiyar bututun bawul ne coaxial, sabõda haka, servo motor iya tura bawul core a cikin bawul bututun ƙarfe smoothly, in ba haka ba zai haifar da lalacewa ga sassa. Tsayawa tsarin injina ko ƙananan bugun siginonin lantarki na iya haifar da ɗan sabani a cikin aikin haɗin gwiwa. A sakamakon haka, bayan da aka haɗa maɓallin bawul, aikin samun iska bai dace ba, kuma tsayin taro bai cancanta ba, wanda ke haifar da gazawar samfurin. An yi la'akari da wannan batu sosai a cikin tsarin tsarin, ana amfani da ganowar iska da kuma gano tsayi don warware samfurori mara kyau.

Lokacin aikawa: Satumba-09-2022